Ansi Buttweld Fittings – Dimensional Tolerances

CROSS-SECTIONAL TOLERANCES FOR ALL BUTTWELDING FITTINGS (ASME/ANSI B16.9 AND B16.28):

| Nominal Pipe Size (NPS) | All Fittings | ||||

| OD at Bevel | ID at Bevel ± | Wall thickness | |||

| in | mm | in | mm | ||

| ½ to 2½ | +0.06, -0.03 | +1.6, -0.8 | 0.03 | 0.8 | Not less than 87.5% of nominal wall thickness |

| 3 to 3½ | ±0.6 | ±1.6 | 0.06 | 1.6 | |

| 4 | ±0.6 | ±1.6 | 0.06 | 1.6 | |

| 5 to 6 | +0.09, -0.06 | +2.4, -1.6 | 0.06 | 1.6 | |

| 8 | +0.09, -0.06 | +2.4, -1.6 | 0.06 | 1.6 | |

| 10 | +0.16, -0.12 | +4.0, -3.2 | 0.12 | 3.2 | |

| 12 to 18 | +0.16, -0.12 | +4.0, -3.2 | 0.12 | 3.2 | |

| 20 to 24 | +0.25, -0.19 | +6.4, -4.8 | 0.19 | 4.8 | |

| 26 to 30 | +0.25, -0.19 | +6.4, -4.8 | 0.19 | 4.8 | |

| 32 to 48 | +0.25, -0.19 | +6.4, -4.8 | 0.19 | 4.8 | |

DIMENSIONAL TOLERANCES FOR ELBOWS AND RETURNS (ASME/ANSI B16.9 & B16.28):

| Nominal Pipe Size (NPS) | 90° & 45° Long Radius Elbows 90° Short Radius Elbows and Tees | 180° Returns | ||||

| Centre-to-End Dimension ± A, B | Centre-to-Centre Dimension ± B (=2 x A) | Back-to-Face Dimension ± C | ||||

| in | mm | in | mm | in | mm | |

| ½ to 2½ | 0.06 | 2 | 0.25 | 6 | 0.25 | 6 |

| 3 to 3½ | 0.06 | 2 | 0.25 | 6 | 0.25 | 6 |

| 4 | 0.06 | 2 | 0.25 | 6 | 0.25 | 6 |

| 5 to 6 | 0.06 | 2 | 0.25 | 6 | 0.25 | 6 |

| 8 | 0.06 | 2 | 0.25 | 6 | 0.25 | 6 |

| 10 | 0.09 | 2 | 0.38 | 10 | 0.25 | 6 |

| 12 to 18 | 0.09 | 2 | 0.38 | 10 | 0.25 | 6 |

| 20 to 24 | 0.09 | 2 | 0.38 | 10 | 0.25 | 6 |

| 26 to 30 | 0.12 | 3 | – | – | – | – |

| 32 to 48 | 0.19 | 5 | – | – | – | – |

DIMENSIONAL TOLERANCES FOR REDUCERS, CAPS AND STUB ENDS (ASME/ANSI B16.9):

| Nominal Pipe Size (NPS) | Reducers & Lap Joint Stub Ends | Caps | Lap Joint Stub Ends | |||||

| Overall Length ± A | Overall Length ± A | OD of Lap B | Fillet Radius of Lap B | |||||

| in | mm | in | mm | in | mm | in | mm | |

| ½ to 2½ | 0.06 | 2 | 0.12 | 3 | +0 | +0, -1 | +0 | +0, -1 |

| 3 to 3½ | 0.06 | 2 | 0.12 | 3 | +0, -0.03 | +0, -1 | +0, -0.03 | +0, -1 |

| 4 | 0.06 | 2 | 0.12 | 3 | +0, -0.03 | +0, -1 | +0, -0.06 | +0, -2 |

| 5 to 6 | 0.06 | 2 | 0.25 | 6 | +0, -0.03 | +0, -1 | +0, -0.06 | +0, -2 |

| 8 | 0.06 | 2 | 0.25 | 6 | +0, -0.03 | +0, -1 | +0, -0.06 | +0, -2 |

| 10 | 0.09 | 2 | 0.25 | 6 | +0, -0.06 | +0, -2 | +0, -0.06 | +0, -2 |

| 12 to 18 | 0.09 | 2 | 0.25 | 6 | +0, -0.06 | +0, -2 | +0, -0.06 | +0, -2 |

| 20 to 24 | 0.09 | 2 | 0.25 | 6 | +0, -0.06 | +0, -2 | +0, -0.06 | +0, -2 |

| 26 to 30 | 0.19 | 5 | 0.38 | 10 | – | – | – | – |

| 32 to 48 | 0.19 | 5 | 0.38 | 10 | – | – | – | – |

ALIGNMENT TOLERANCES (ASME/ANSI B16.9):

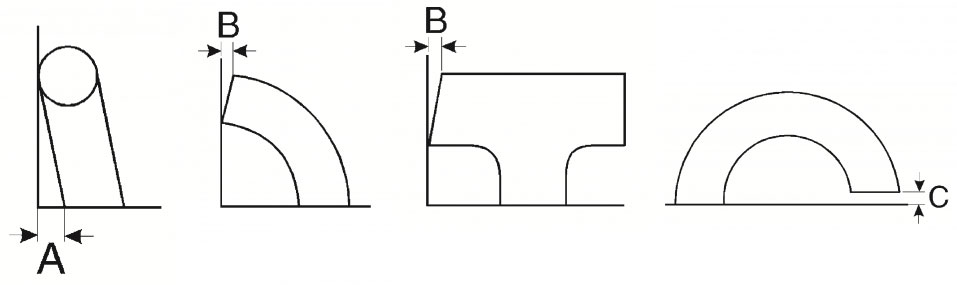

Alignment tolerances are concerned with the way that the ends of a fitting are cut. Exaggerated distortions are shown for clarity in the diagram below.

| Nominal Pipe Size (NPS) | Off Plane Tolerances, ± A | Off Angle Tolerances, ± B | Alignment of Ends, ± C | |||

| in | mm | in | mm | in | mm | |

| ½ to 4 | 0.06 | 2 | 0.03 | 1 | 0.03 | 1 |

| 5 to 8 | 0.12 | 4 | 0.06 | 2 | 0.03 | 1 |

| 10 to 12 | 0.19 | 5 | 0.09 | 2 | 0.06 | 2 |

| 14 to 16 | 0.25 | 6 | 0.09 | 3 | 0.06 | 2 |

| 18 to 24 | 0.38 | 10 | 0.12 | 4 | 0.06 | 2 |

| 26 to 30 | 0.38 | 10 | 0.19 | 5 | – | – |

| 32 to 42 | 0.50 | 13 | 0.19 | 5 | – | – |

| 44 to 48 | 0.75 | 19 | 0.19 | 5 | – | – |

Dimensional Tolerances for reducers, caps and stub ends (ASME/ANSI B16.9)

DIMENSIONS AND TOLERANCES MSS SP-43:

MSS SP-43 only covers buttweld fittings made for use with Schedule 5S and 10S pipe as defined in ANSI/ASME B36.19M (plus short pattern stub ends suitable for use with Schedule 40S pipe). The dimensions and tolerances defined in MSS SP-43 are substantially the same as those in ASME/ANSI specifications (½ to 24 in).

- MSS SP-43 tolerances (including alignment tolerance) are the same as for ASME/ANSI B16.9 and B16.28 except with regard to the outside diameter at the bevel:

- Tolerance of OD at Bevel =

± 0.03 in for NPS ½ to 4

+0.06, -0.03 in for NPS 5 to 8

+0.09, -0.03 in for NPS 10 to 18

+0.12, to -0.03 in for NPS 20 to 24

BUTTWELD FITTINGS AVAILABLE MATERIALS AND GRADES

- Inconel 625 Buttweld Fittings

- Inconel 660 Buttweld Fittings

- Inconel 690 Buttweld Fittings

- Inconel 718 Buttweld Fittings

- Inconel 825 Buttweld Fittings

- Inconel 800 Buttweld Fittings

- Titanium Grade 2 Buttweld Fittings

- Titanium Grade 5 Buttweld Fittings

- Duplex S31803 Buttweld Fittings

- Duplex S32205 Buttweld Fittings

- Super duplex S32520 Buttweld Fittings

- Super duplex S32750 Buttweld Fittings

- Hastelloy C22 Buttweld Fittings

- Hastelloy C276 Buttweld Fittings

- Monel 400 Buttweld Fittings

- Monel K500 Buttweld Fittings

- Stainless Steel 316TI Buttweld Fittings

- Stainless Steel 904L Buttweld Fittings

- Copper nickel 90/10 Buttweld Fittings

- Copper nickel 70/30 Buttweld Fittings

- Alloy 20 Buttweld Fittings

- Nickel 200 Buttweld Fittings

- Nickel 201 Buttweld Fittings

Comments

Post a Comment